Everything You Need to Know About Electric Diaphragm Pumps

Electric diaphragm pumps, also known as electric operated double diaphragm pumps are a type of positive displacement pump that harnesses an electric motor to operate a flexible diaphragms. In contrast to pumps that depend on rotating blades, electric diaphragm pumps generate suction and pressure through the reciprocating motion of the diaphragm. This innovative design comes with multiple benefits, making electric diaphragm pumps an attractive option for various industries.

How Do Electric Diaphragm Pumps Operate?

Typically, an electric diaphragm pump comprises of a casing, a diaphragm, a driving mechanism (motor), and some check valves. The electric motor powers either a camshaft or linkage mechanism, causing the diaphragm to move back and forth. When the diaphragm contracts inwardly (stroke), it increases the chamber volume, creating a vacuum that pulls fluid into the pump chamber through the inlet check valve. Conversely, when the diaphragm expands outwardly (stroke), it reduces the chamber volume, pushing fluid out through the discharge check valve.

There are two configurations of electric diaphragm pumps:

- Single diaphragm pumps: These pumps employ one diaphragm for fluid transfer and are typically used in applications requiring lower flow rates and pressures.

- Double-diaphragm pumps: Double-diaphragm pumps, also known as electric operated double diaphragm pumps (EODD Pump), utilise two diaphragms separated by a chamber filled with a fluid, like oil. The movement of one diaphragm transfers pressure to the other, creating a design that enables higher flow rates and pressures compared to single diaphragm pumps.

Advantages of Electric Diaphragm Pumps

Electric diaphragm pumps offer benefits over other pump types, making them a preferred option for different applications. Here are some key advantages:

- Self-priming: Electric diaphragm pumps have the ability to self-prime, allowing them to remove air from the line and start pumping without requiring pre-filling with liquid. This feature is particularly useful when the pump is situated above the source.

- Dry-run capability: In contrast to pumps that can incur damage if operated without electric diaphragm, EODD pump can function safely even when the fluid source runs dry.

- Handling solids and shear-sensitive fluids: Thanks to their positive displacement design, electric diaphragm pumps can effectively manage fluids with suspended solids or abrasive particles. Their pumping action minimises shear stress on fluids, making them suitable for shear liquids like paints and pigments, polymers, latex solutions, slurries, mayonnaise, ketchup and sauces, creams and shampoos, coatings, milk, and oil emulsion.

- Accurate dosing: Electric diaphragm pumps offer dosing control, making them perfect for applications that require precise chemical or fluid dosing.

- Energy efficient: Compared to air-operated diaphragm pumps, electric diaphragm pumps are more energy efficient, resulting in lower operating costs.

- Quiet operation: Electric diaphragm pumps produce less noise than other pump types.

- Easy maintenance: Their simple design allows EODD Pumps to offer lower maintenance costs with minimal downtime.

Applications of Electric Diaphragm Pumps

Electric diaphragm pumps are versatile. They find diverse applications across industries. Some common examples include:

- Transferring chemicals in chemical processing

- Pumping food-grade liquids in food and beverage processing

- Dosing pharmaceuticals in the pharmaceutical industry

They are also used in industries such as:

- Water treatment

- Printing

- Paint and coatings

The construction sector also used EODD pumps for applications like:

- Grout pumping

- Dewatering

Agriculture sector uses diaphragm pumps for:

- Spraying pesticides and fertilizers

Selecting the Right Electric Diaphragm Pump

When choosing a diaphragm pump for your needs, there are a few key factors to take into account:

- Flow rate and pressure requirements: First, you’ll need to determine the flow rate (amount per time unit) and pressure (force per area unit) for your use. This will help you in choosing the pump with exact specifications to satisfy your needs.

- Fluid type: It’s important to think about whether the materials of the pump’s materials are compatible with the fluid it will be handling. Electric diaphragm pumps come with wetted parts (such as diaphragms and valves) made from materials like steel, PTFE (Teflon), or Santoprene to ensure they work well with various fluids.

- Viscosity: The thickness of the fluid (its resistance to flow) can impact how well the pump performs. While electric diaphragm pumps can handle a range of viscosities, it’s essential to choose one that’s suitable for handling your specific viscosity level.

- Particle size: If your fluid contains particles, consider the particle size that the pump can effectively handle.

- Portability: Depending on where you plan to use it, portability might be a factor worth considering. Electric diaphragm pumps are generally compact and lightweight, making them convenient for applications.

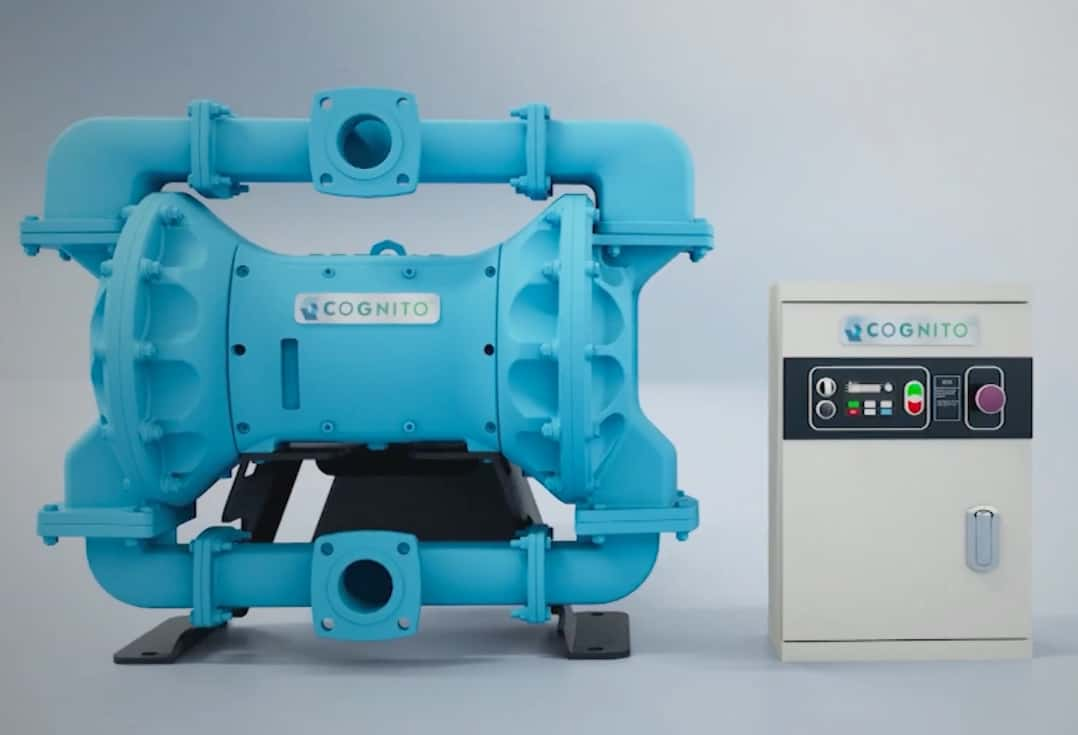

Cognito: A Dynamic Electric Diaphragm Pump

In the world of electric diaphragm pumps, IDEX shines as a manufacturer recognized for its dedication to quality and innovative solutions.

Their commitment to excellence is evident in their Cognito line of electric diaphragm pumps, which are tailored to deliver top-notch performance and user satisfaction.

Cognito Electric Operated Double Diaphragm Pumps

The IDEX Cognito series showcases electric operated double diaphragm pumps, renowned for their robustness and capability to tackle demanding tasks. These pumps encompass the advantages of diaphragm pumps, like:

- Self-priming

- Dry run resistance, and

- Handling of solid materials

They also provide added benefits apart from the ones listed above.

- CognitoTM Advantage: This exclusive technology by IDEX utilizes an IoT-enabled system for monitoring and analysis of pump performance. It enables real-time data collection for maintenance and enhanced process optimization.

- Cognito SmartInsights: Expanding on the CognitoTM Advantage Cognito SmartInsights offers data analysis to pinpoint issues and fine-tune pump operation for optimal efficiency.

- Material Choices: The IDEX Cognito Electric Operated Double Diaphragm pumps present a range of options for pump components to meet chemical compatibility requirements.

Selecting a Cognito Electric Operated Double Diaphragm Pump

By opting for an IDEX Cognito Electric Operated Double Diaphragm pump, you leverage the expertise of IDEX’s engineering prowess along with features found in the Cognito series. When evaluating your options, remember to take into account these aspects in addition to the selection criteria mentioned earlier:

- Different Cognito Models: IDEX Cognito provides a range of Electric Operated Double Diaphragm pump models with varying flow rates and pressure capabilities tailored to suit your specific application needs accurately.

- Utilising Data: If remote monitoring and leveraging data for process optimisation are crucial for your operations, features like CognitoTM Advantage and CognitoSmartInsights from IDEX Cognito can offer significant benefits for you.

By teaming up with IDEX Cognito, you not only get access to top-notch electric diaphragm pumps but also a holistic solution that:

- Boosts pump efficiency

- Simplifies maintenance tasks, and

- Enables data-informed decision-making for your industrial processes

Conclusion

Electric diaphragm pumps present a solution for an array of industrial applications that demand reliable, versatile, and efficient fluid transfer solutions. Their ability to carry self-prime runs, manage solids, and work with shear fluids makes them highly valuable across diverse industries. When selecting an electric diaphragm pump, factor in considerations such as flow rate, pressure requirements, fluid characteristics, and portability specific to your application.

For users looking to enhance performance and adopt data-driven management practices effectively, the range of IDEX Cognito Electric Operated Double Diaphragm pumps serves as an ideal choice.

The Cognito stands out for its design functionalities, such as CognitoTM Advantage and Cognito SmartInsights, and a range of material choices. It’s an option for individuals looking to enhance their operations.

Whether you need a dependable electric diaphragm pump or a sophisticated system with remote monitoring features, there’s an electric diaphragm pump that fits your requirements perfectly. Discover the options on offer. Harness the power of electric diaphragm pumps for your industrial needs.

Get Support Now

Related Articles

The Evolution of Pump Technology: A Guide to Electric Diaphragm Pumps

Cognito EODD the Best in Class Diaphragm Pump

Diaphragm Pump and Its Uses in the Paint Industry

See How Cognito Can Support Your Pumping Operation

Contact an expert to learn how our electronically operated double diaphragm pumps can increase efficiency and ROI for your pumping operation.